We recently crossed another project milestone by completing the first design stage documentation towards the Green Homes certification awarded by the Indian Green Building Council

We are targeting the gold level certification and will be among the first green certified homes in Goa.

Some of Nivim's main green features are listed below. We will try to do detailed write-ups on some of these in future posts.

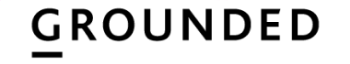

Trees and preserving site’s unique features

– Our project site had 14 existing trees before construction and we preserved these trees and incorporated them in our design. The design also retains nearly 35-40% of the site as natural landscape. New landscape is planted with majority local species to have minimal need for irrigation water use.

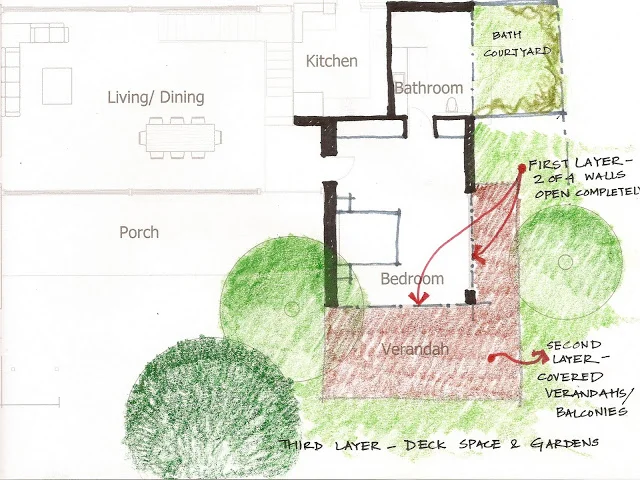

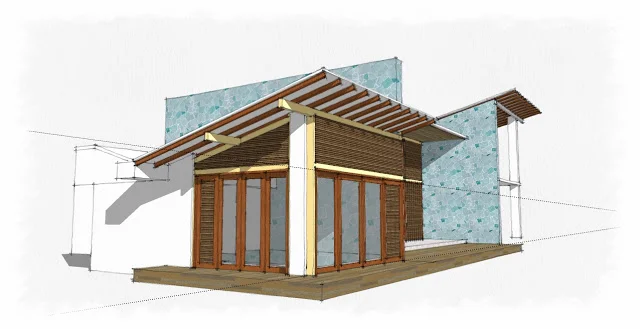

Building orientation and design

– The main house building is oriented with the longer façade facing North-South to minimize direct sun exposure on east and west where the sun is lower increasing heat absorption. Ample shading devices have been planned to further reduce sun exposure and heat intake.

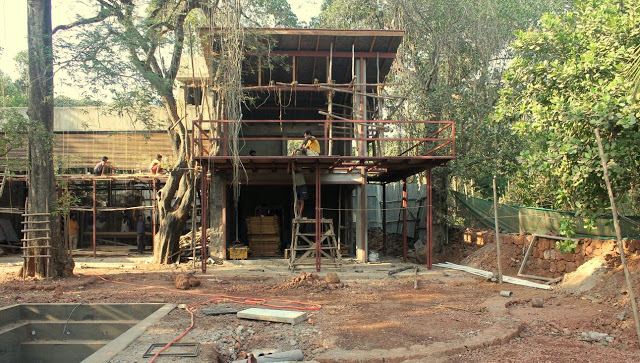

Daylighting and cross ventilation

– 100% of living spaces are designed to be adequately day lit with ample shading and openings for cross ventilation. This eliminates the need for any artificial lighting or mechanical cooling during the day saving energy use and providing healthy indoor air quality.

Energy

– 100% use of solar power for water heating. Use of 3-star energy efficient refrigerator (40%less energy use) and 5-star rated air-conditioners (25% less energy use). Use of solar control glass on east and west façade to reduce heat absorption to indoors.

Cool Roof

– 75% of roof is finished with highly reflected material to reflect sun’s heat thus help in maintaining lower temperature in living areas below.

Two openable walls per room provides 100% daylighting and cross ventilation

Water

– We are collecting 50% of rainwater runoff from the roof and storing it for future use for landscaping and for swimming pool use. Prioritized use of low-flow fixtures in the bathrooms saving 30% of water without having any impact on perceived flow of water and use. We are treating 100% of our grey water* on-site to be used for landscaping thus further reducing pressure on municipal water resources.

* Grey water is all water from bathrooms and kitchen drainage except water from the toilets. Grey water is filtered on-site through a root zone water treatment system.

Permeable paving

– 75% of site’s paved surfaces are built using permeable paving to allow maximum percolation of rain water back into the ground.

Construction Materials

– Use of over 50% building material from within 500kms of the site to reduce embodied energy spent in transporting materials over long distances. Encouraged reuse of salvaged building material as well as building material with high recycled content such as fly-ash bricks, fly-ash cement, recycled tetrapak boards, aluminum and reclaimed wood. Reducing the use of cement** in construction by building load bearing walls and filler slabs.

**Cement production is known to produce large quantities of greenhouse gases, for every ton of cement produced one ton of GHGs are released in the atmosphere. GHGs are known to be the leading cause for climate change. Read more here.

Low VOC paints

–Use of low VOC external and internal paint to reduce exposure to hazardouschemicals to humans.

List of green certified buildings in India, http://www.igbc.in/site/igbc/certifiedbuilding.jsp