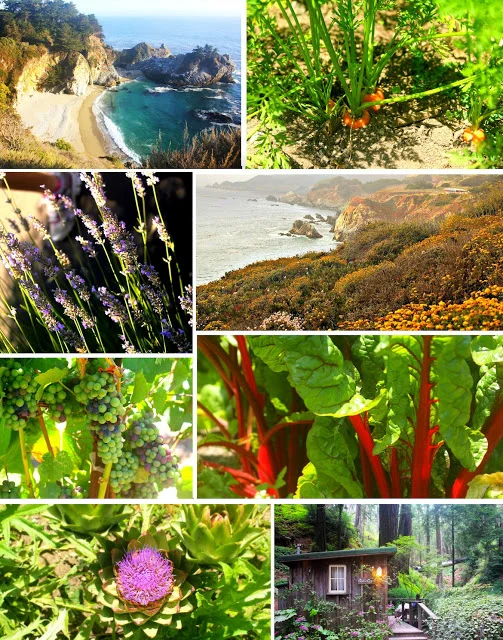

Sample of a fixed louvered section of the opening built on-site for review

Another interesting functional design feature in our external opening design is that the fixed louver panels will actually be fitted with mosquito nets and have a sliding glass door behind them. This is our proposed solution after various design iterations to address the following conflicting factors that influence living in Goa:

- the ability to keep the doors open for as long as one can to connect with nature

- the insurgence of mosquitoes at dusk specially during monsoons

- the ability to allow for cross ventilation at all times of day even when there are mosquitoes, or if it is raining, or for any other reason the doors need to be kept closed

- the need to make the space air-tight if the use of mechanical air-conditioning is needed

Attention to details such as this comes only from living in a place through the seasons to know peculiarities in climate and livability. Trust me, I wish I had mosquito nets in the openings in my house that allowed cross ventilation, did not block my view, were easy to clean, not stuck with velcro, did not obstruct my ability to open and close my windows and most importantly kept the mosquitoes out but the breeze in.

Another key success of adding nets to the openings is enabling cross ventilation at all times and reducing the need for mechanical air-conditioning at all times of the day throughout the year. This reduces the energy requirement of the house and the pressure of added development on the land.

As a result of our opening design, 100% of our living spaces are daylit. This is based on the math that shows that 100% of our living area has a daylight factor of at least 2%. (Daylight Factor = Window Area/ Floor Area X Actual Visible Transmittance X Constant)

In addition, 100% of our living spaces have access to fresh air ventilation. This calculation is based on the area of openable windows as a proportion of the living area of each room.

Both these statistics far exceed the standards for Indoor Air Quality as mandated by leading green guidelines as being critical to healthy living.

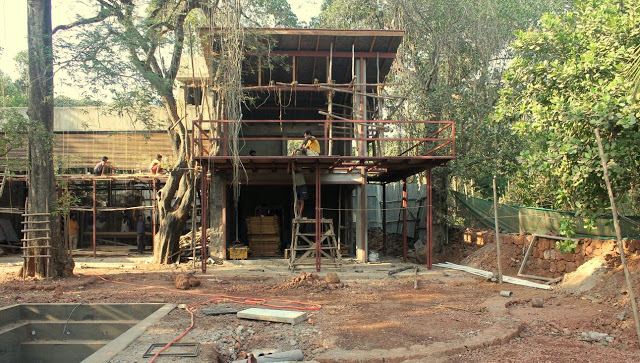

So far so good. looking forward to more happy discoveries and experiments in the remaining 40%.