I was recently interviewed by National Geographic for their upcoming documentary on Green Buildings in India. The following was my response to them and it lists my views in a nutshell on the topic. I hope I do not sound too angry, disappointed or disgruntled... the truth of the matter is that we have a long way to go to make green buildings as mainstream commercial and day-to-day construction practice in India today.

_________________________________________________________

Dear Mr. Producer

Thank you for your email. I am an IGBC accredited professional in India and a LEED accredited professional in the US. I am architect and have been working in the design and construction industry in New York for many years.

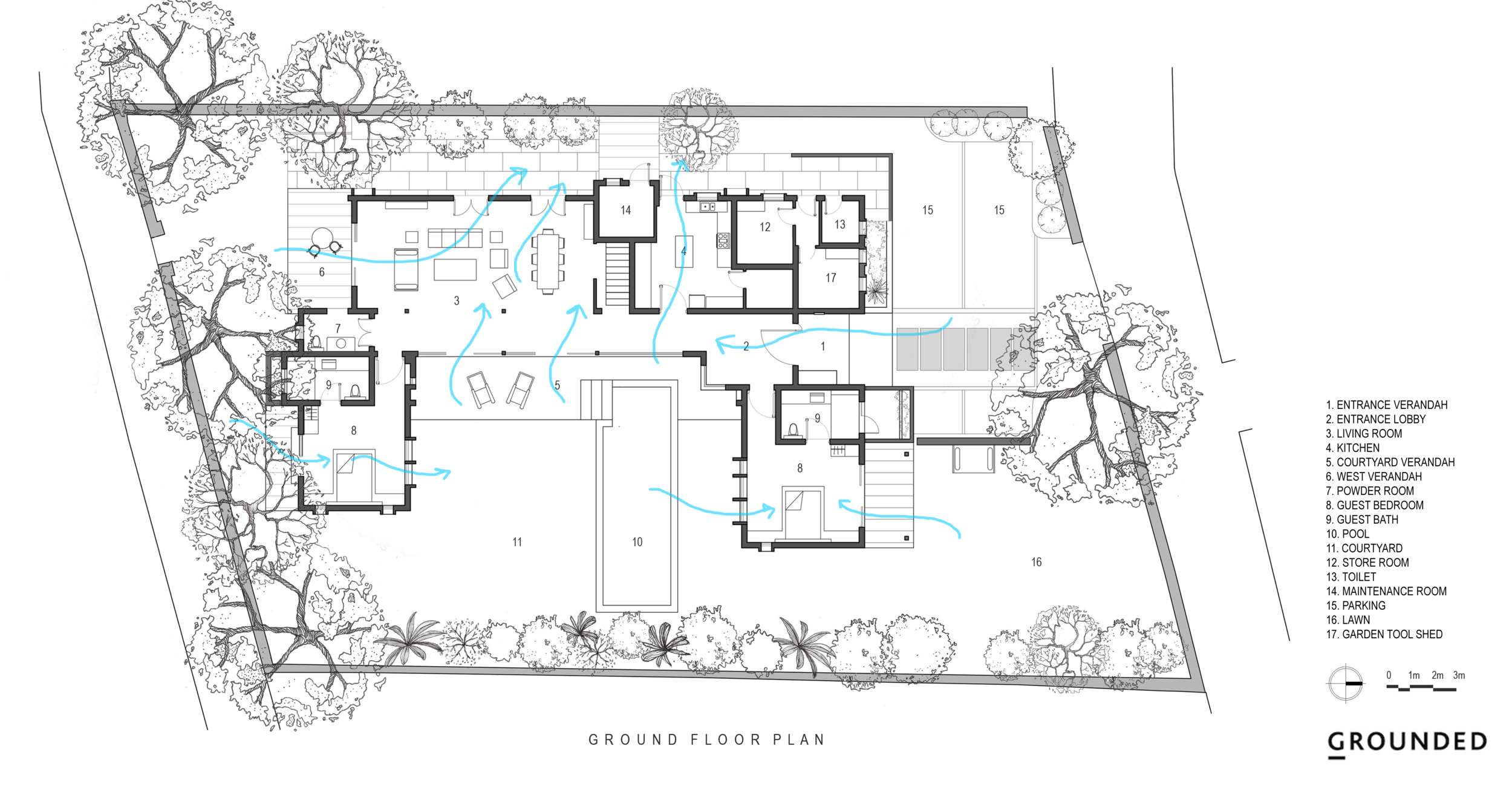

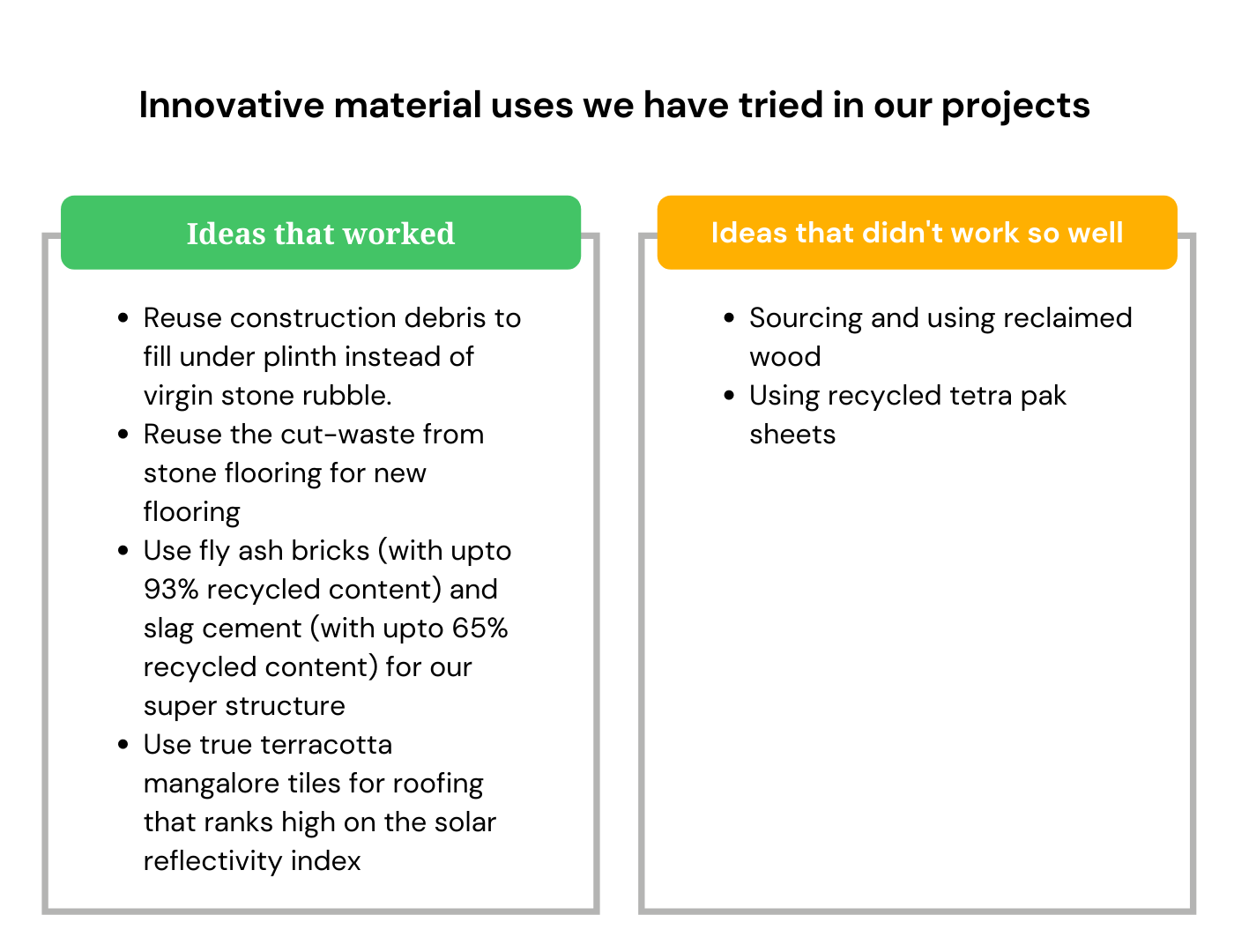

For the last year and a half, I have been busy in building the first green certified home in Goa. We are aiming for the Gold IGBC Green Homes certification. What makes the project unique is that we have considered and employed strategies from the three green ideologies that exist in India today:

-

The age old traditional common sense building principles such as building orientation, retaining existing trees and building around them, courtyard plan, load bearing walls, etc.

-

The alternative building strategies such as filler slabs, reducing use of cement, prioritizing use of existing material on-site, recycle and reuse of wastewater, etc.

-

The new cutting edge technologies such as solar water heater, environment-friendly HVAC systems, moisture sensors, electric sensors, electric vehicles, low VOC paints, green roof, etc.

Unfortunately in India today these three streams of sustainability exist in individual silos and are not really working together. Everyone seems to be doing their own thing while commercial developers have joined the green building bandwagon only as eyewash to improve marketability and sales

The biggest challenges to green buildings in India are the vast regional climatic variations, perceived high cost, lack of usable information, material procurement, labor training, lax regulatory environment, lack of incentives and lack of education on the need for green building among contractors, building material manufacturers, vendors and the final consumers.

Organizations such as IGBC, TERI and CSE have done a good job of educating and training the architecture community. There is also awareness among the global material manufacturers and suppliers. But sadly, there is still long way to go when it comes to training the remaining regional/ local participants of the construction industry. It would actually be fun if you walk through a local building materials market in your city and simply ask the vendors and buyers ‘what is green building’. This could result in an amusing montage on the state of green building in India and how far we still have to go.

We are building in a small state of Goa and have faced challenges in procuring items as simple as low-flow water fixtures. We are now accustomed to receiving blank stares from vendors, public officials and neighboring community at the mention of the word ‘Green Building’. An interesting anecdote is my conversation with my neighbor who was shocked at our plan to construct recharge pits to percolate rain water back into the earth. Her state of utter shock (and some extent distrust) stemmed from the fact that she could not comprehend why we would spend money on something that did not give us anything back. When I explained that sometimes actions need to be based on the larger common good and not only immediate personal gain, I was honored with the same blank stare…

It is surprising that in a state with a high percentage green cover, a rich agrarian culture, low population and density, the residents frequently complain about lack of adequate water supply. Goa is a coastal state and receives a very high amount of 3metres in rainfall every year. Still the water table around our site has been dropping over the years. The same neighbor as above attempted to dig a well in their property many years back and did not find water at decent depth. The obvious problem is that we are using resources at a much faster pace than the earth can replenish. This problem is of course much more pressing in cities but it is a shame when you find it in the seemingly green paradise of Goa. As with the rest of India, Goa is experiencing a building boom. The responsibility of builders to preserve this fragile remaining slice of extremely biodiverse and sensitive environment is extremely critical.

Green building is responsible building. Among global consumption of resources, buildings account for: 20% of water use; 25-40% of energy use; 30-40% of solid waste generation; 30-40% GHG emissions; and 40% of use of raw materials. While building anything, even a tiny house, one must understand that we are utilizing material, energy and water in construction, and changing the ecology of the site and surroundings forever. Plus, we are adding to the demand for resources for as long as the life of the building.

Another favorite statistic that should be a wake-up call to the current mainstream building practices in India is that the production of Portland cement accounts for 5 - 8% of global greenhouse gas (GHG) emissions, the major cause of climate change. The high emissions are due to the chemical process that produces cement and as a by-product generates large amounts of carbon dioxide. One ton of GHG is released with every one ton of cement production. These figures are shocking and must be considered while thoughtless construction of concrete frame-structure building and hardscaping of open areas.

I have added brief notes to your questionnaire. Your show can go a long way in educating the common man about the need and benefits of building green. I hope that you will attempt to dig deep into the subject. I wish you best for your project.

I am adding some biographical information about myself below. For more information on our project in Goa, you can visit:

http://www.newyorkgoadiaries.com/

http://www.newyorkgoadiaries.com/search/label/Green%20Building

Best

Anjali