We have been at final finishing stage for the last three months and at this point I feel like I can see the finish line, feel it but just can't reach it... so here is me venting...big time....

We have had a major exodus of labor at Diwali... All labor went home for the festival and we are left with 2 labor + 2 painters on our site for the past 3 weeks ++ our electrical sub-contractor has been sick, has had a surgery and has disappeared with zero contact... Add to this inefficiency from the landscaper, a slow plumber and stubborn painters... the result is that we are just weeks away from completing the project before FF&E but just can't seem to wrap it up.

FF&E stands for Furniture, Fixture and Equipment, in our case that includes the kitchen and closet cabinetry, movable furniture and equipment. Only once we complete the messy construction phase can we move to the next. Most light fixtures are already on-site waiting to be fixed and most furniture has already been bought and is waiting in warehouses to be delivered....And that makes the situation even more frustrating... when we have planned ahead and made sure that all pieces from our end are ready, but we just can't move ahead ....

The other frustrating aspect of this situation is my inability to control the situation.. I had no inkling that labor would leave, and now have practically no control in the time it takes to get them back on-site. Lessons learned, more control, more communication.... ?? is that possible ?

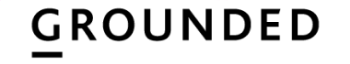

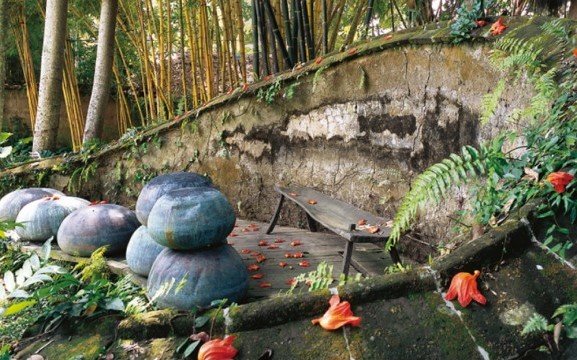

Below are pictures of the spaces as they look now. I almost feel like picking up the paint brush and broom and clean the place up myself.

LIVING ROOM INTERIOR @Nov. 2012:

BEDROOM INTERIOR @Nov. 2012:

BATHROOM INTERIOR @Nov. 2012:

MASTER BATHROOM INTERIOR @Nov. 2012:

PS: there is a surprise element above the wash basin counter in master bathroom... which we hope to reveal soon !